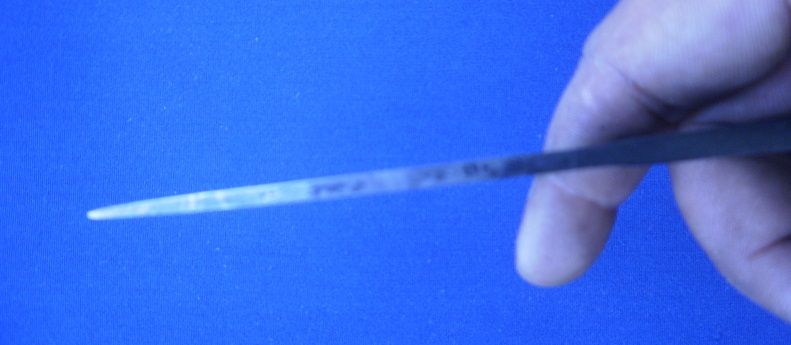

After a lil handheld disc sander work

Working with the stone and sandpaper

Post shaping, grinding and HT. HT was as follows

1. Heated to nonmagnetic plus 2 minutes. This happened surprisingly fast. In 15 minutes it was glowing bright red so I tested it with a magnet and it slid off.

2. Quenched in fresh peanut oil for 90 Seconds after the flame went out. It flamed for maybe 4 seconds as I dipped and moved the blade around.

3. Let it cool until I could hold it in my hand.

4. Heated it until I got a dull glow again. Took another 3 mins and a few seconds.

5 Let it cool in its own time.

6. Hardness testing-

Tested with another file on the edge and it slid right off. Also I had banged the edge against a granite counter top to test hardness and to see if the edge chips or rolls before the HT. Edge rolled about a mm. I tried the same thing after HT and there was a little silvery edge roll but I had to look with a hand-lens to find it. And there is a small chip on the kitchen counter top I am hoping my wife doesn't notice

Dim: 7.5 Inches with 3.5 to 4 inch blade depending where UR measuring from. 4.5mm thick at the base of the grind tapering off towards the tip.

Inspirations

Spyderco Mules- For the blade shape and the proper FFG with the distal taper.

CRK Nyala, J. Neilsen BUK, Lon Humphrey Brut de Forge were my inspirations for the general shape of the knife.